-

The high-temperature industry is the earliest and most widely applied field for tungsten and molybdenum metals. Tungsten and molybdenum metal materials possess high melting points, low vapor pressures, low thermal expansion coefficients, as well as excellent high-temperature strength and resistance to creep, enabling them to meet the stringent requirements of materials for high-temperature furnaces, heating elements, and heat treatment vessels. Kaitong Molybdenum&Tungsten's products fully leverage the high-temperature performance of tungsten and molybdenum materials, resulting in superior quality, longer lifespan, and lower production costs.

The Kaitong Molybdenum&TungstenTechnical team can provide furnace design solutions and issue complete sets of drawings based on factors such as thermal zone space, current, power, and more. We tailor these solutions to meet your specific requirements for the thermal zone and its various factors. Starting from powder, we ensure material quality through rigorous process flow and mature technical processes. Additionally, we guarantee quick delivery cycles.

-

For different high-temperature furnace usage environments and temperatures, we offer a wider range of molybdenum materials and alloys. By selecting the most suitable materials, we aim to enhance production efficiency.

Material Science Application Service temperature Pure molybdenum Heater, heat shield <1200℃ Mo-La-C1 Heater, heat shield <1400℃ Mo-La-C2 Heater, heat shield <1600℃ AKS-Mo Heater, heat shield <1800℃ TZM Vacuum furnace parts <1600℃ MHC Vacuum furnace parts <1400℃ Lanthanum tungsten Heating element, heat shield, vacuum furnace parts 1800-2000℃ AKS-Tungsten Heating element, heat shield, vacuum furnace parts 2000-2500℃

-

Molybdenum and Tungsten materials possess high melting point, low vapor pressure, low coefficient of thermal expansion, along with excellent high-temperature strength and resistance to creep.

Molybdenum and Tungsten materials possess high melting point, low vapor pressure, low coefficient of thermal expansion, along with excellent high-temperature strength and resistance to creep. -

Ion implantation requires materials with high-temperature performance and resistance to chemical erosion. Tungsten molybdenum materials are predominantly used for the main components of ion chambers due to their excellent properties in these regards.

Ion implantation requires materials with high-temperature performance and resistance to chemical erosion. Tungsten molybdenum materials are predominantly used for the main components of ion chambers due to their excellent properties in these regards. -

By adding a layer of molybdenum liner to the graphite crucible (molybdenum-lined crucible), the temperature of the crystal rod is controlled, thereby increasing the pulling speed of the crystal.

By adding a layer of molybdenum liner to the graphite crucible (molybdenum-lined crucible), the temperature of the crystal rod is controlled, thereby increasing the pulling speed of the crystal. -

The main technical parameters of tungsten crucible spinning products are as follows: Density: 18.5±0.2 g/cm³. Composition: Compliant with national standards: ≥99.95%.

The main technical parameters of tungsten crucible spinning products are as follows: Density: 18.5±0.2 g/cm³. Composition: Compliant with national standards: ≥99.95%. -

The quartz glass melting and ceramic melting industries provide customers with mature and stable tungsten molybdenum components for high-temperature melting.

The quartz glass melting and ceramic melting industries provide customers with mature and stable tungsten molybdenum components for high-temperature melting. -

We offer high-purity materials with exceptionally stable performance, ideal for growing various heterostructure materials and ultra-thin epitaxial layers.

We offer high-purity materials with exceptionally stable performance, ideal for growing various heterostructure materials and ultra-thin epitaxial layers. -

We provide tungsten molybdenum components for lighting technology manufacturing, primarily used in LED light source production, contributing to energy conservation and environmental protection.

We provide tungsten molybdenum components for lighting technology manufacturing, primarily used in LED light source production, contributing to energy conservation and environmental protection. -

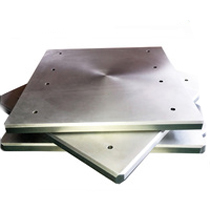

We offer high-purity sputtering targets with excellent density and corrosion resistance. Binding services are available.

We offer high-purity sputtering targets with excellent density and corrosion resistance. Binding services are available. -

High-density tungsten-based alloys: W-Ni-Cu, W-Ni-Fe, Mo-Cu, W-Cu

High-density tungsten-based alloys: W-Ni-Cu, W-Ni-Fe, Mo-Cu, W-Cu -

In medical imaging, the molybdenum target receives X-rays and generates images. Molybdenum is also one of the key materials in X-ray tubes.

In medical imaging, the molybdenum target receives X-rays and generates images. Molybdenum is also one of the key materials in X-ray tubes. -

Tungsten ribbon, tungsten-molybdenum electrodes, tungsten-molybdenum alloy welding wire

Tungsten ribbon, tungsten-molybdenum electrodes, tungsten-molybdenum alloy welding wire -

Glass melting electrode; Molybdenum electrode arm; Tungsten-molybdenum material rack; Molybdenum heat shield; Tungsten-molybdenum crucible; Tungsten-molybdenum material table

Glass melting electrode; Molybdenum electrode arm; Tungsten-molybdenum material rack; Molybdenum heat shield; Tungsten-molybdenum crucible; Tungsten-molybdenum material table